Teaching Staff:

G.-C. Vosniakos

Course Description:

1. History-evolution and typology.

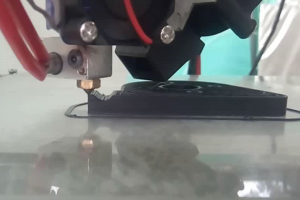

2. Material extrusion (FDM, FFF). Mechanics of material flowing through a nozzle. Processing of polymers, bio-polymers, polymer matrix composites. 3D printers: assembly and motion control. Robotic arms as printers. Machining parameters, printer parameters and link to product quality.

3. Powder Bed Fusion (SLS/SLM). Laser matter interaction during melting and sintering.

Melt pool, solidification, transformations of metallic materials. Fusion of non-metallic materials. SLS/SLM machines: assembly and control based on melt pool characteristics. Machining parameters, machine parameters and product quality.

4. Pot curing (SLA). Resin polymerization processes using monochromatic light and other sources. SLA machines and layer thickness control. Machining parameters, printing parameters and product quality.

5. Other methods (direct energy deposition (DED), material jetting, binder jetting, sheet lamination). Material joining mechanisms. Principles of operation of the relevant machine tools. Processing parameters, limitations and product quality.

6. Choice of AM method – case studies. Comparison with conventional processes and with other AM processes. Post-processing. Overview of the range of processed materials in general applications. Special applications of materials and methods in biomechanics, biomedicine, aerospace. Future applications and new materials.

7. CAD/CAM interface. Layer design, trajectory design, relative constraints and optimization. CAM-slicers systems for layer and trajectory determination. Standards (STL, AMF etc).

Coursework:

1 lab and 2 project assignments

Link (login required):

https://helios.ntua.gr/course/view.php?id=5647