HydroFSP

Leader: Professor D. Manolakos

Funded by: Basic Research Program PEVE 2020 – ELKE NTUA

Amount (€):

Timeframe:

The aim of HydroFSP project is the investigation of hydrogen embrittlement in Friction Stir Processed (FSPed) specimens of two aluminum alloys with different microstructures.

The chosen aluminium alloys are the AA5083-H111 alloy and the AA6082-T6 alloy. Both alloys are essential in many fields of nowadays industrial manufacturing. Respectively, the first alloy belongs to the category of non-heat-treatable aluminum alloys, while the second belongs to that of heat-treatable alloys.

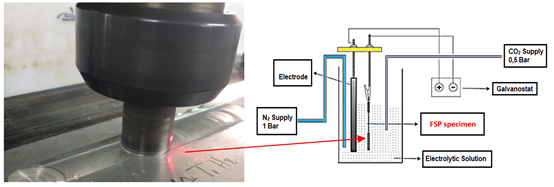

The main object of this study is the comparison of the basic mechanical and surface properties of the two original aluminum alloys as well as of those of the Friction Stir Processed alloys both under ambient conditions and after the influence of embrittlement due to hydrogen diffusion phenomenon. The study will include macrostructural and microstructural characterization by the use of stereoscopic analysis, optical microscopy, scanning electron microscopy and EBSD analytical technique. Furthermore, within the framework of this project, tensile tests under slow strain rate modes will be performed both before and after the electrochemical polarization in the hydrogenated environment of the FSPed specimens.

Overall, the present basic research will contribute to the development of expertise in order to determine the evolution of synergistic mechanisms concerning the hydrogen effect on the mechanical properties of FSPed aluminum alloys, which are widely applied in many innovative sectors both in scientific and industrial field.