SAMPLE PROJECTS

Project Description:

Digitising a large snail-type centrifugal pump

Product application:

CAD model construction for use in casting model making

Approach:

IScan white light scanner by IMetric: 74.414.442 triangles for the shell and 45.410.114 triangles for the sand casting core at an accuracy of 0.3 mm

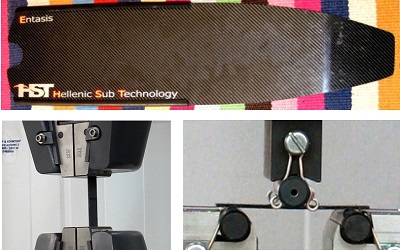

Project Description:

Determining the mechanical properties of handmade composite fins that are manufactured with several layers of carbon fabrics

Product application:

Used for diving and snorkeling

Approach:

Tensile testing and 3-point bending following ASTM standards

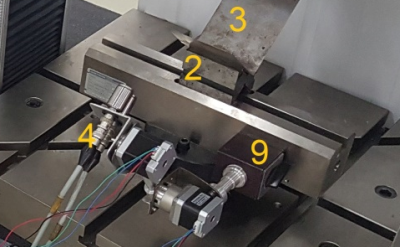

Project Description:

Development of a medum cost capacitive device for measuring the sheet bending angle in press brakes to <0.1 degrees

Product application:

Used for automatic measurement of sheet bendng angle (especially after spring back) in cnc brakes

Approach:

Two degree of freedom miniature arm with geometric calculations and auto calibration

Project Description:

Manufacturing a prototype metal flange to evaluate material and achieved tolerances

Product application:

Used in corrosive environments

Approach:

3-axis CNC milling using custom made fixturing and evaluation of cutting parameter combinations

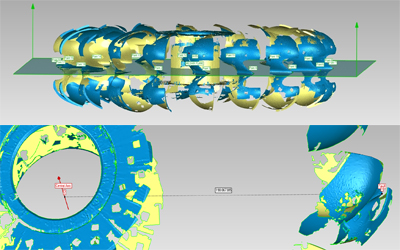

Project Description:

Determining the geometrical accuracy of a Pelton wheel

Product application:

Used for power generation in hydroelectric facilities

Approach:

White light scanning using the IScan system in selected areas of interest and post-processing of point cloud to derive a partial digitised model of the Pelton wheel.

Calculation of the relative bucket positions in the axial and radial directions as well as the angular distance between buckets.

Project Description:

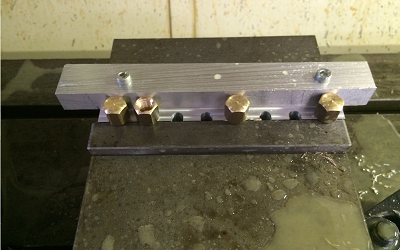

Manufacturing of brass end fittings

Product application:

Used in water installations

Approach:

CNC machining (turning, milling) using custom made fixturing that could accomodate several workpieces in one setup to minimize changeover time and increase production rate

Project Description:

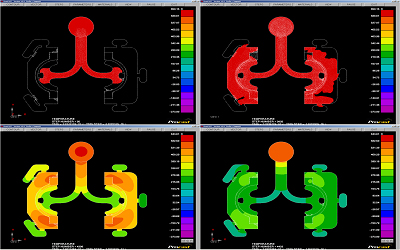

Evaluating the die design of an aluminum alloy part manufactured through high-pressure die casting (HPDC)

Product application:

Used in automotive applications

Approach:

FEA simulations to evaluate molten metal flow, temperature distribution and solidification time.

Development of data-driven models to predict possible defects and optimise process parameters.